- Home

- Printing equipment

- Finishing equipment

- Auxiliary equipment

- Auxiliary Systems

- Consumables

- Services

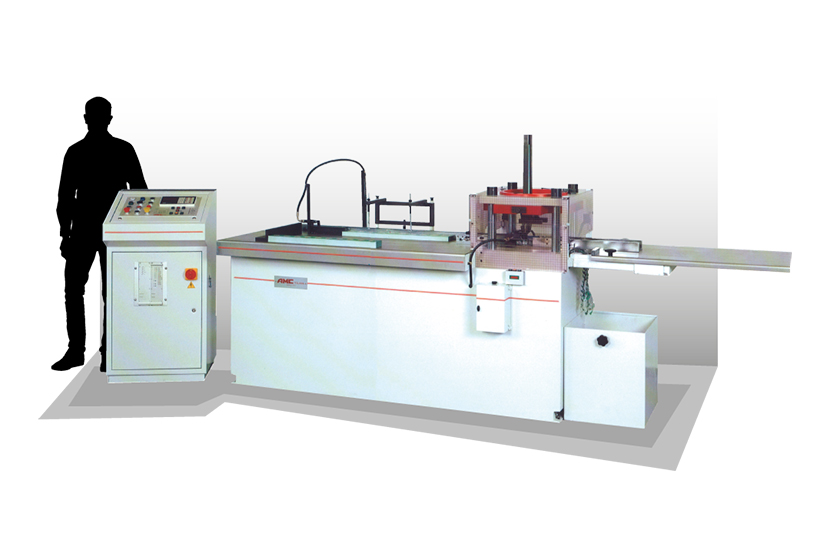

This machine, BF 1000- 10 F, is the result of decades of development in the flat bed die-cutting sector and, when related to other brands’ products, it offers many key market benefits. The machine allows you to cut many sheets at the same time (from 10 up to 30), its sheet production is minimum 5000 sheets per hour and maximum 14000 sheets per hour. It is a full-hydraulic, four columns vertical press and its maximum cutting pressure is 180 Tons. It has four mechanical stops and they can be electronically controlled in order to set the machine cutting depth. The machine supports traditional steal made die-cutting devices/ wooden “American” devices.

This die-cutting machine is recommended for PPC, IML, such plastic materials, and paper cutting processes and automatic labels collecting processes. There’s also a four axes touch screen system, which allows you to get a sheet placement tolerance of 0,03mm.

It is a vertical press, completely hydraulic, four mechanical stops and is controlled electronically on the axis of travel of the sheet. This machine is suitable for semi-rigid/rigid materials, such as paper, cardboard and PVC. The machine uses a traditional American die, which can be easily replaced by the operator.

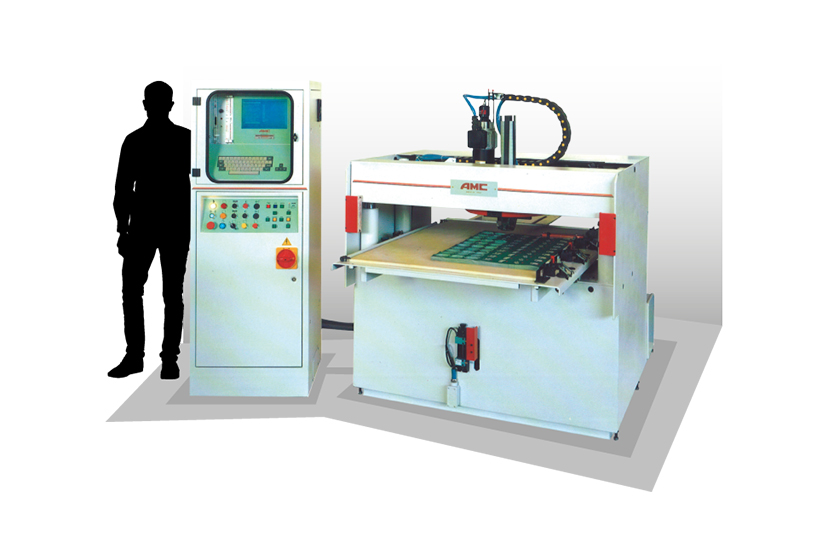

Fully hydraulic, suitable for the production of all types of label materials (paper, plastic, cardboard, etc..) and forms straight from a stack of sheets.

All die-cutted labels (except for very large sizes) are stacked on a collector, while the scrap remains on the table. The NC collect can support a device, which rotates the die of 360°, in order to cut upturned images, with great paper saving and with the correction of each label or of the whole program.

Cutting can be done at any angle and sequence desired. The control of each operation is managed by a panel, TFT display, with management of the pages and interface that you can personalize by PC.

Computerized label punching machine, fully hydraulic, suitable for the production of all types of label materials (paper, plastic, cardboard, etc..) and for different forms, directly from a stack of sheets. All die-cutted labels (except for very large sizes) are stacked on a collector, while the crop remains on the table.

The machine can accommodate a 360 ° rotation of the die for die cutting and inverted images, with great savings of paper and with correction of each label or the entire program, and cutting can be done at any angle and desired sequence.

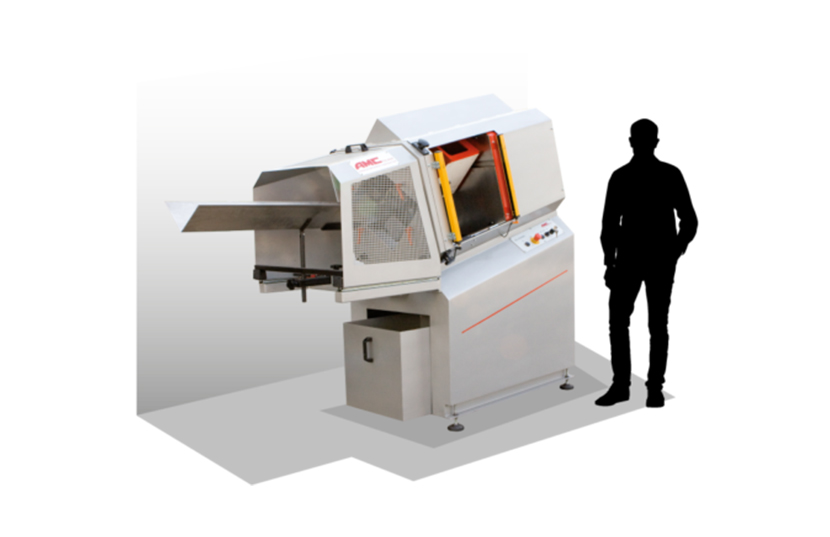

Microcomputerized label punching machine, is fully hydraulic, developed to die cut paper strips. The MCS is an excellent machine for producing a wide variety of bottle neck-labels for champagne, wine and cards, etc. A considerable saving of paper is permitted by special punching system.

MCS has two different unloadig devices for punched labels. Small and medium sized labels are pushed up through the die while the waste comes down into a steel container. Big labels are pushed down after die cutting by a mechanical device with a compression spring.

Labels come out of the punching section onto an unloading table. The die is affixed by means of four adjusting clamps. Changeover of dies takes a few minutes. The MCS die cuts within a tolerance of 0,025 mm and the production is up to 400.000 labels per hour.

Completely hydraulic machine suitable for the Rapid Sec & Rapid Carboard production of any kind of labels, cards, envelopes, 3 knife trimming of books and round cornering, etc.

The average production is 900.000 labels per hour. It is equipped with a steel cube which is self-adjustable in every position on the V-shaped support, onto which straight-cut stacks are placed in order to obtain a uniform pressure on the paper. The die is locked in by four centering clamps.

Every adjustement allowing the perfect centering of the images is made on the V-shaped support. Photoelettric cells and guarding are provided for safety. Die change in less than 5 minutes allows for economical low, and medium production runs as well as hight volume production.