- Home

- Printing equipment

- Finishing equipment

- Auxiliary equipment

- Auxiliary Systems

- Consumables

- Services

The solvents used in the industry are proved to be a problem for environmental protection, the health of the individuals using it and last but not least the costs of acquisition and their disposal.

Solvent recycling is the solution for all the above mentioned:

IST washing systems offer the ideal cleaning solution for different component parts in the printing industry.

A wide range of products is available, which can meet all the requirements of small or large customers.

The washing systems offer a complete solution for optimizing and reducing the washing time of the parts.

If you need an equipment that can accurately wash flexographic plates, with the lowest chemical consumption, Flexomatic is the right machine.

Being dedicated to washing photopolymer plates after removing them from print, the equipment is automatic and easy to operate. Robust and compact, it is suitable for cleaning UV, solvent-based and water-based inks.

Available versions: 45 (450 mm), 65 (650 mm), 95 (950 mm) and 120 (1200 mm).

You can store either sleeves or anilox rollers and the system being portable, you can move it around exactly where you need it.

Storage capacity: 10 sleeves for wideband printing or 20 sleeves for narrowband printing.

Available in different sizes with adjustable height.

Caresonic created the MK III system for the label producers. The small dimensions allow it to be installed on a simple bench.

Caresonic systems can efficiently and safely clean the ceramic anilox rollers, no matter the dimension of the cells. It includes cleaning systems, in one cycle, for 1/2/3 or 4 anilox rollers with different diameters.

The Cellsonic NW range of systems is intended for manufacturers of narrow-label labels with a high production volume. The basic systems are for 4 or 6 anilox rollers, but can be adapted according to the specific requirements of each client.

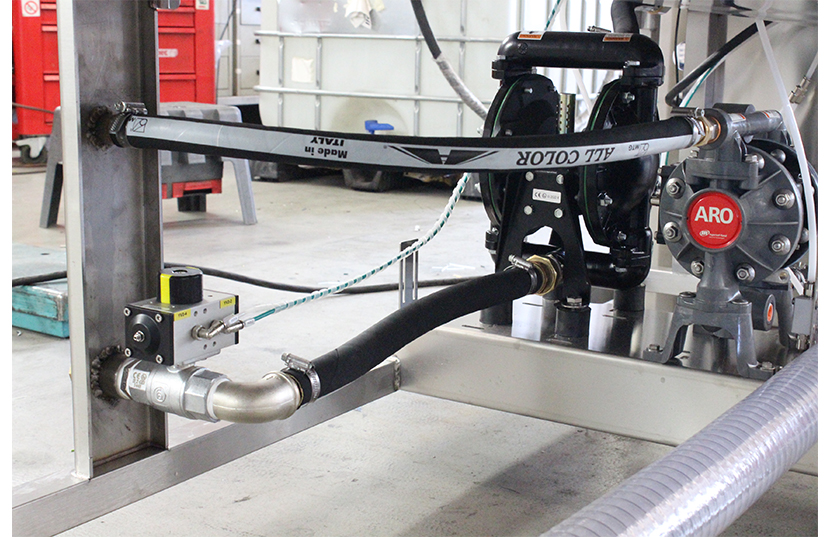

Flocculation plants are designed and developed for the treatment of wastewater containing non-biodegradable soluble pollutants, such as inert minerals, organic substances, mineral oils, detergents and solvents, paints or residues of suspended organic substances. The operating principle is the use of flocculating agents that destroy colloidal systems through a series of chemical transformations leading to obtaining recoverable waste that can be discharged into a container.

Demineralisation is a chemical-physical treatment process of water intended for the elimination, in whole or in part, of dissolved salts. It can be achieved in two different ways: either by using ion exchange resins or by reverse osmosis.

Water Energy reverse osmosis systems, of the series WO, are based on the phenomenon that occurs when to the surface of a semi-permeable membrane, which separates two solutions with different concentration, is applied a pressure difference versus and higher than osmotic pressure, so that the solvent flow occurs from the more concentrated to the more diluted solution. Reverse osmosis is one of the technologies used to desalinate sea water.