- Home

- Printing equipment

- Finishing equipment

- Auxiliary equipment

- Auxiliary Systems

- Consumables

- Services

Tehnical Specifications

Applications

Substrate

Tehnical Specifications

Applications

Substrate

Tehnical Specifications

Applications

Substrate

Tehnical Specifications

Applications

Substrate

The LAMINASTRIPE unit laminates holograms on paper or cardboard, by thermal transfer.

Tehnical Specifications

Applications

Substrate

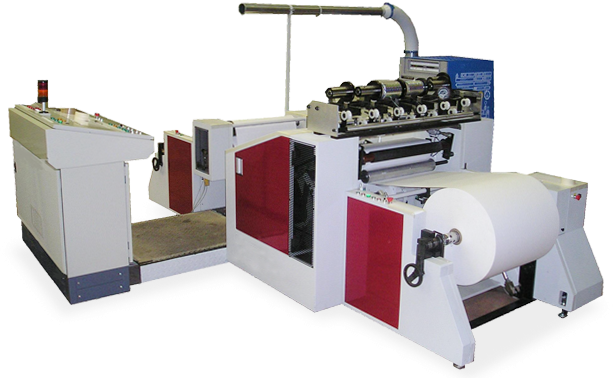

The equipment allows wax lamination, wax coating and hot melt. It can be used both for conventional applications in the food industry and the cosmetics industry, as well as for new applications such as paper or PET wrap-around labels.

Tehnical Specifications

Applications

Substrate