- Home

- Printing equipment

- Finishing equipment

- Auxiliary equipment

- Auxiliary Systems

- Consumables

- Services

Tehnical Specifications

Applications

Substrate

Tehnical Specifications

Applications

Substrate

Tehnical Specifications

Applications

Substrate

Tehnical Specifications

Applications

Substrate

The LAMINASTRIPE unit laminates holograms on paper or cardboard, by thermal transfer.

Tehnical Specifications

Applications

Substrate

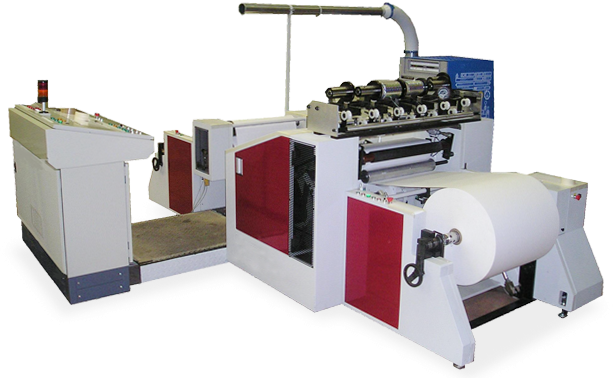

The equipment allows wax lamination, wax coating and hot melt. It can be used both for conventional applications in the food and cosmetics industry, as well as for new applications such as paper or PET wrap-around labels.

Tehnical Specifications

Applications

Substrate

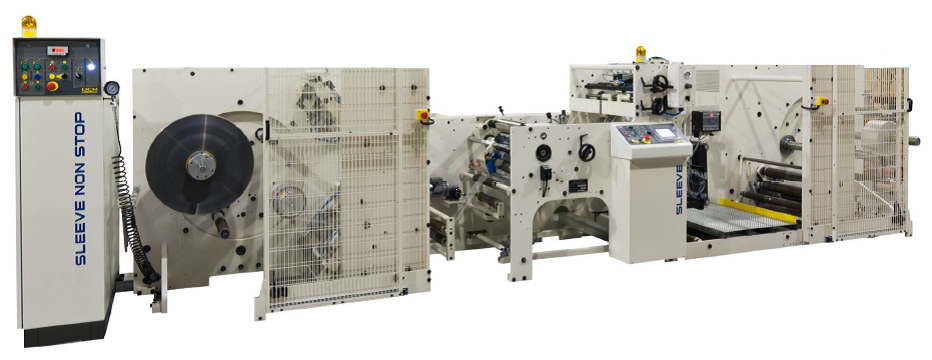

DCM produces and develops machines for shrinkable labels for more than 25 years. With over 500 installations worldwide, DCM offers a latest generation equipment which meets the needs of the present label market.

Tehnical Specifications

Applications

Substrate

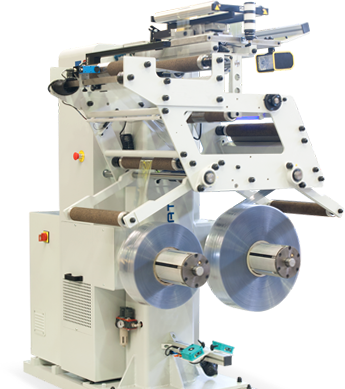

Tehnical Specifications

Applications

Substrate

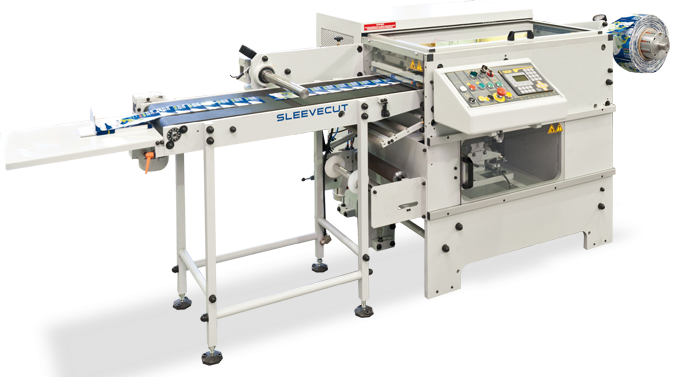

Tehnical Specifications

Applications

Substrate

This compact flexo printing machine can be used to print corrugated cardboard, flat cardboard and paper formats in one or two colours. It is also possible to apply any type of varnish or adhesive with suitable stereos. An optional automatic feeder can be used to increase the productivity of the printing machine.

Tehnical Specifications

Applications

Substrate

This flexo printing machine is very practical for printing small or medium-sized runs of paper or plastic bags in one to three colours in register using a conveyor. Upon exit from the printing section, the bags are ejected onto a rotating platform for drying.

Tehnical Specifications

Applications

Substrate