- Home

- Printing equipment

- Finishing equipment

- Auxiliary equipment

- Auxiliary Systems

- Consumables

- Services

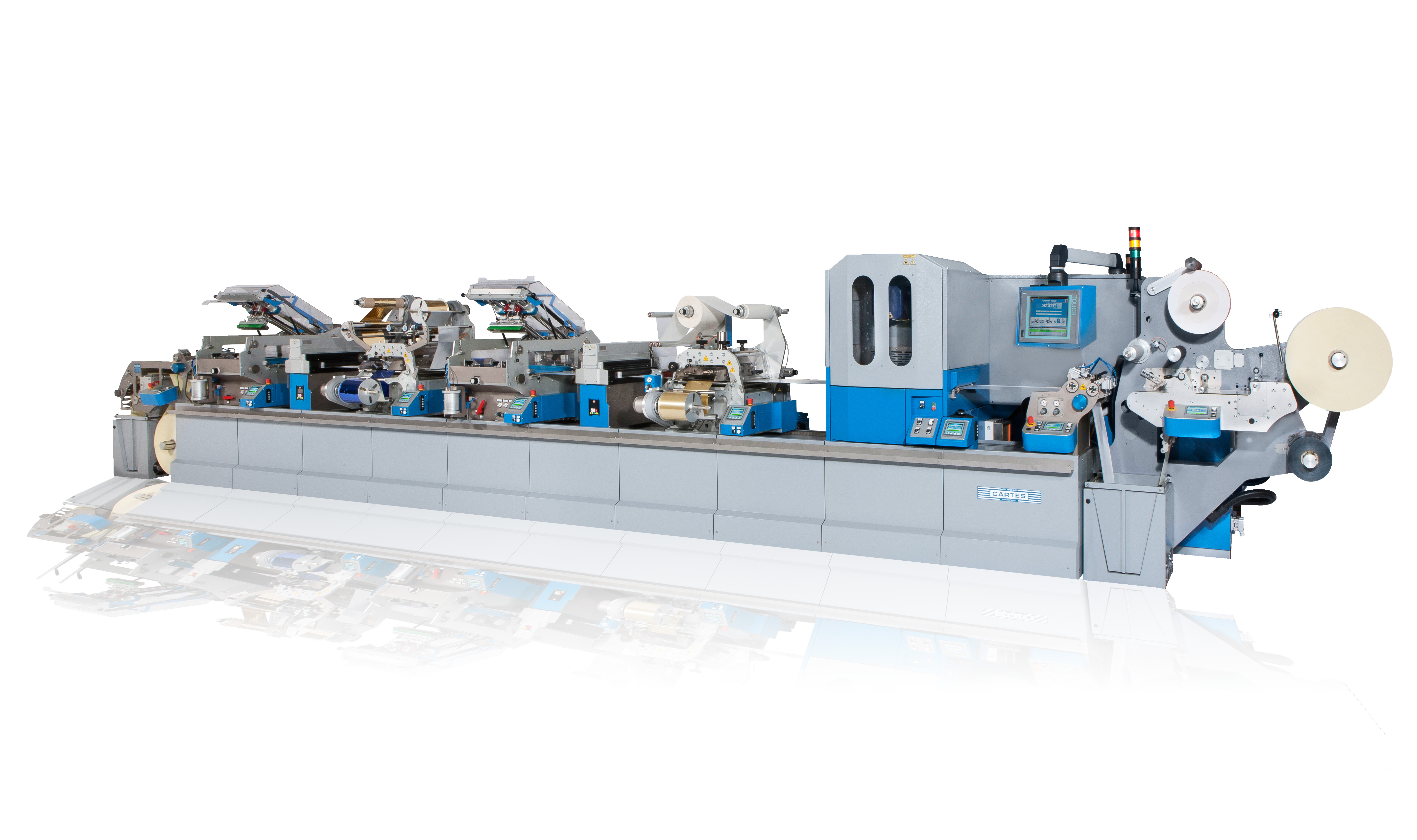

GT Series Cartes has managed to develop a unique and innovative technology, which allows the operator to obtain the best results both for short and long runs. Besides the fact that GT360 is a robust platform, capable to deliver high quality finishing at any speed, it is also noticed for the following features:

The machine is fully modular and can be configured according to the customer’s needs. Modularity also allows us to retrofit groups.

GEMINI Series represents the new frontier in digital finishing. It is versatile, performant, developed for minimum material loss during set up, having the possibility to save all the parameters of a job with a minimum energy consumption.

Specialized in laser technology, Cartes present the ILC (Invisible Laser Cutting) which cuts the labels on the back to avoid white marks.

IM2 is a compact, sheet-fed flexo printing equipment that can be used to print corrugated cardboard, cardboard and various paper sizes in one or two colors. With the help of this equipment it can be used to varnish or apply various types of adhesive on materials compatible with these products.

Tehnical Specifications

Applications

Substrate

This flexo printing machine is very practical for printing small or medium-sized runs of paper or plastic bags in one to three colours in register using a conveyor. Upon exit from the printing section, the bags are ejected onto a rotating platform for drying.

Tehnical Specifications

Applications

Substrate