- Home

- Printing equipment

- Finishing equipment

- Auxiliary equipment

- Auxiliary Systems

- Consumables

- Services

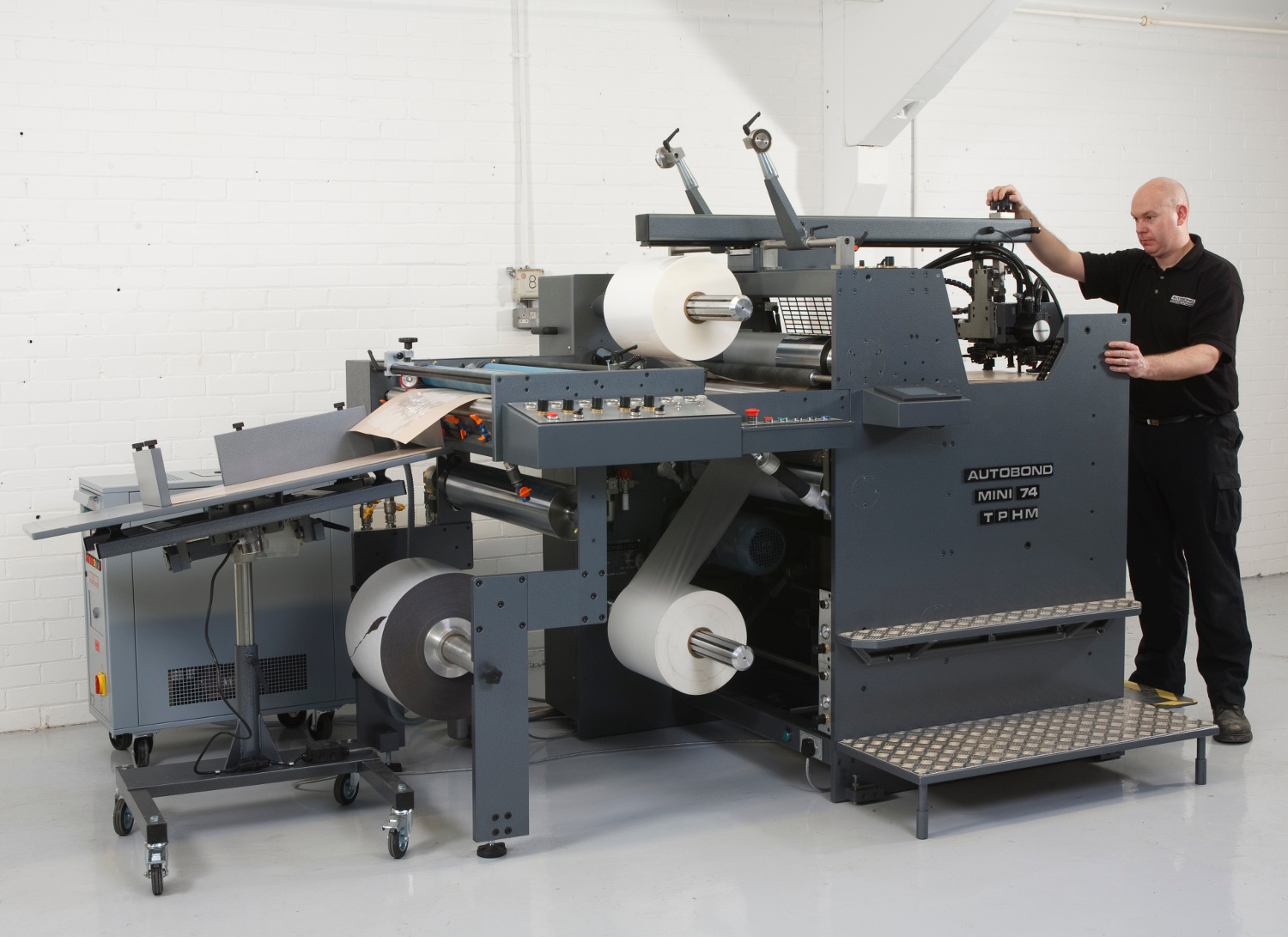

High speed equipment – 60 m/min, with maximum 74 cm x 52 cm format and minimum 32 cm x 22.5 cm format.

The sheets are picked up by means of a Heidelberg Speedmaster 74 feed head, driven by a servomotor. The sheets are taken over and guided by a system of suction cups. This system allows feeding with sheets from a pallet with a maximum height of 1.2 m. The minimum sheet thickness is 90 gsm and the maximum thickness is 650 gsm.

The roll of film is mounted on a quick-change airshaft with film tension controlled by a pneumatic brake.

There are two laminating rollers. A highly polished 150 mm diameter chrome roller and a 150 mm diameter rubber roller. The chrome roller is heated with a sophisticated Swiss made temperature control unit (TCU)

The bump sheeter runs in-line. Sheets are delivered into a vibrating jogger table on wheels.

The machine includes a digital sheet counter, adjustable curl-bar, pneumatically adjustable in-feed nip rollers and pneumatic air clutch for constant tension between the laminator and the sheeter.