- Home

- Printing equipment

- Finishing equipment

- Auxiliary equipment

- Auxiliary Systems

- Consumables

- Services

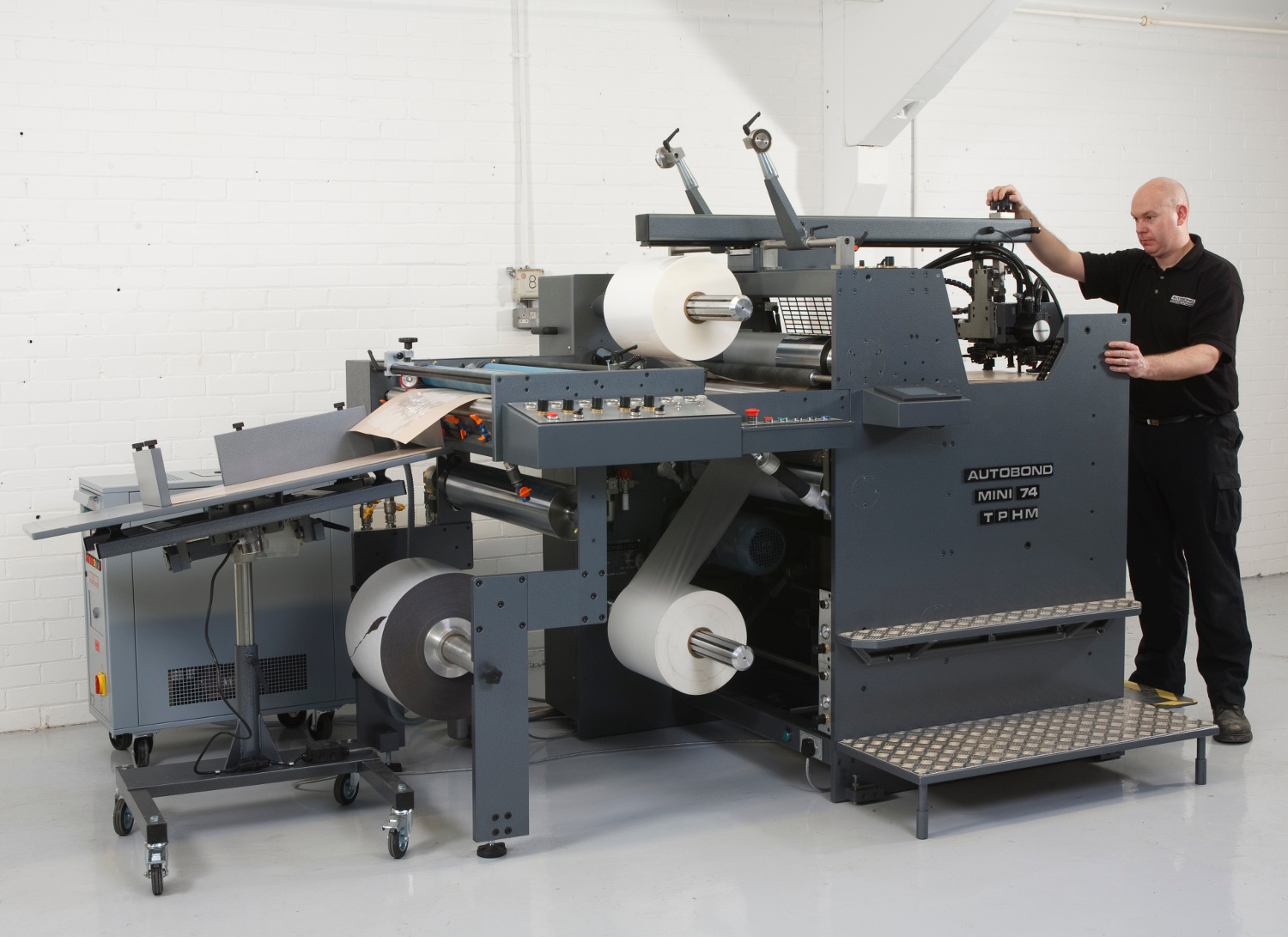

Thermal laminating equipment with a production speed of 45 m/min for a maximum 74 cm x 52 cm format and a minimum 32 cm x 22.5 cm format. The minimum thickness of the sheets is 115 gsm and the maximum is 650 gsm.

The takeover of sheets if made with a Heidelberg-Stahl suction drum.

The tensioning of the laminating film is made with a pneumatic clutch. The reel is mounted and fixed on a quick-change inflatable air shaft. The lamination is made by a chrome roller - 150 mm in diameter- which is water heated, and a rubber roller also 150 mm in diameter. Pressure control is made by a pneumatic system.

Delivery into vibrating wheeled jogger table with under-sheet adjustable air control.

The machine is equipped with digital counter, anti-curl bar, feeding rolls pneumatically adjusted, automatic tensioning film system positioned between the laminating part and sheeting part

High speed equipment – 60 m/min, with maximum 74 cm x 52 cm format and minimum 32 cm x 22.5 cm format.

The sheets are picked up by means of a Heidelberg Speedmaster 74 feed head, driven by a servomotor. The sheets are taken over and guided by a system of suction cups. This system allows feeding with sheets from a pallet with a maximum height of 1.2 m. The minimum sheet thickness is 90 gsm and the maximum thickness is 650 gsm.

The roll of film is mounted on a quick-change airshaft with film tension controlled by a pneumatic brake.

There are two laminating rollers. A highly polished 150 mm diameter chrome roller and a 150 mm diameter rubber roller. The chrome roller is heated with a sophisticated Swiss made temperature control unit (TCU)

The bump sheeter runs in-line. Sheets are delivered into a vibrating jogger table on wheels.

The machine includes a digital sheet counter, adjustable curl-bar, pneumatically adjustable in-feed nip rollers and pneumatic air clutch for constant tension between the laminator and the sheeter.

This machine, BF 1000- 10 F, is the result of decades of development in the flat bed die-cutting sector and, when related to other brands’ products, it offers many key market benefits. The machine allows you to cut many sheets at the same time (from 10 up to 30), its sheet production is minimum 5000 sheets per hour and maximum 14000 sheets per hour. It is a full-hydraulic, four columns vertical press and its maximum cutting pressure is 180 Tons. It has four mechanical stops and they can be electronically controlled in order to set the machine cutting depth. The machine supports traditional steal made die-cutting devices/ wooden “American” devices.

The equipment is completely hydraulic and exerts a force of 180 tons. This punch is recommended for materials such as PPC, IML, paper, etc. It also has a 4-axis system for positioning sheets, a system controlled by "touch screen". This system ensures the positioning of the sheets with a tolerance of 0.03 mm.

It is a vertical press, completely hydraulic, four mechanical stops and is controlled electronically on the axis of travel of the sheet. This machine is suitable for semi-rigid/rigid materials, such as paper, cardboard and PVC. The machine uses a traditional American die, which can be easily replaced by the operator.